WATCH AN INTRODUCTION TO SHIP BUILDING & MAINTENANCE

WHAT'S IT ALL ABOUT

Maritime technology is an innovative and advanced manufacturing sector that includes all the phases from the research and design to the construction, maintenance and repair of ships and other maritime structures. The sector comprises shipyards, system, technology and equipment suppliers.

European shipyards build the most high-tech and complex vessels in the global market: cruise ships, ferries, offshore vessels and platforms, fishing vessels, dredgers, research vessels, mega-yachts, naval ships, submarines, aircraft carriers, etc. Building this type of ships is very complex as most of the ships built in Europe are unique prototypes designed according to the specific needs of the owner. The sector is in fact characterised by long development phases and long manufacturing cycles (for example 12 – 24 months for merchant vessels, 24 – 36 months for passenger vessels). Therefore, each vessel is a new challenge.

European maritime equipment and system suppliers develop the technologies required for the operation of each vessel: propulsion, navigation, cargo handling, drilling, surveillance equipment etc. These companies also provide solutions for a broader range of maritime activities such as offshore energy generation (marine energies, offshore wind, electric substations, etc).

- https://www.youtube.com/watch?v=0LEdIQYn_3w This video has been realised by LISNAVE a Portuguese company that represents one of the world’s leading ship repair companies. The video shows the main professions related to the ship repair and maintenance sector.

- https://www.youtube.com/watch?v=Mw06pltMZCw This video has been realised by Navantia, a Spanish state-owned company reference in the design and construction of high technology military and civilian vessels. The video shows the construction process and launching of the future 'Audaz' Maritime Action Ship that Navantia has built for the Spanish Navy in San Fernando, Cadiz.

- https://www.usweproject.eu/ this is the link of the USWE project of which SEA Europe is partner. The project is born in the frame of the European Sectoral Social Dialogue for Shipbuilding with the aim of bringing together industry and workers representatives from all over Europe and education experts to analyse the impact of technological change in existing occupations and future skills needs in shipbuilding

- Ship Design

- Mechanics

- Structural Fabrications

- Electrical Systems

- Plumbing

- Painting/Spray and Gel Coats specialists

- Marine Surveying

- Welding

- Interior Design

Meet professionals working in shipbuilding in the menu Interview.

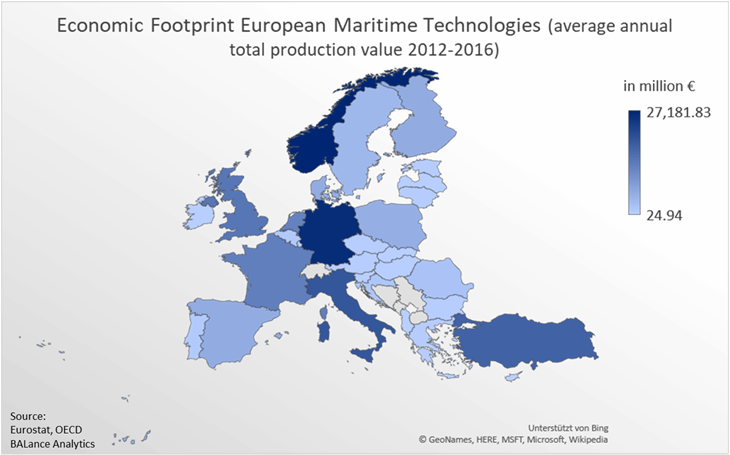

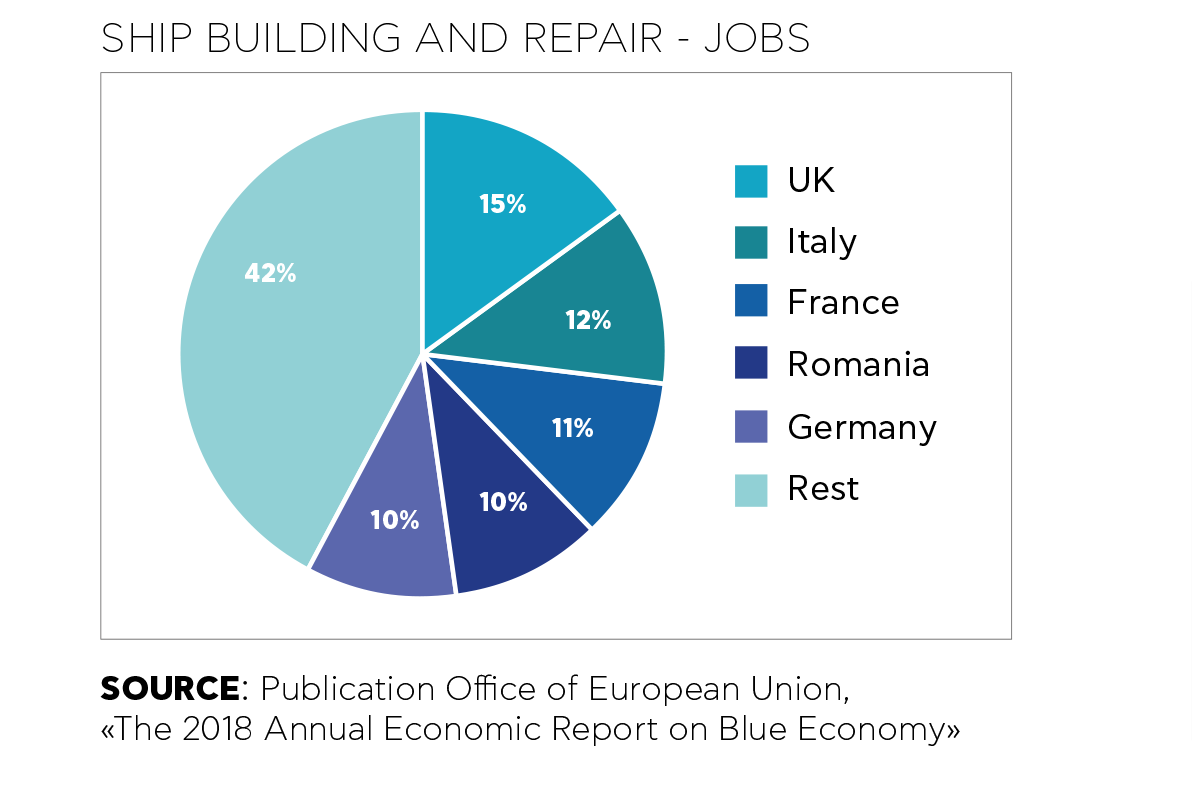

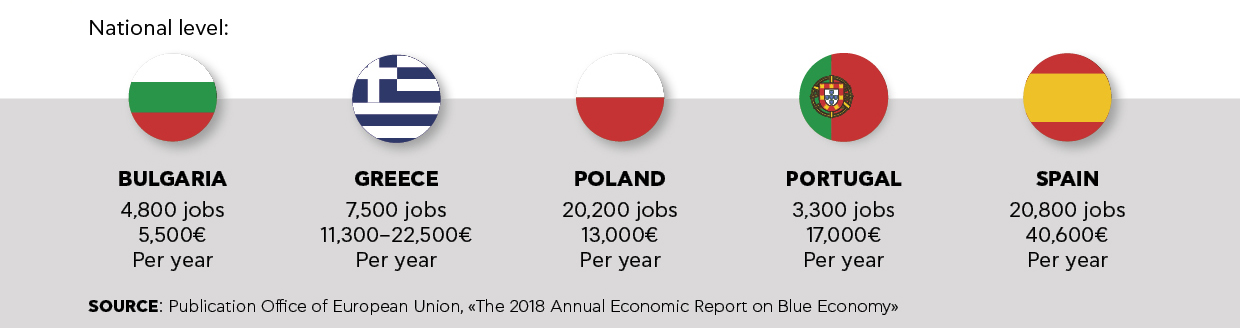

The maritime technology sector is present in most of European countries. Main countries are Bulgaria, Croatia, Denmark, Finland, France, Germany, Greece, Italy, Norway, The Netherlands, Poland, Portugal, Romania, Spain and the United Kingdom.

In areas where there is a relevant shipbuilding industry there is usually a very important supply chain of equipment and service providers which contribute to generate direct and indirect employment.

At newbuilding shipyards and repair, maintenance and conversion shipyards you can work in the designing, building and maintenance of complex vessels, offshore platforms, electric substations, submarines or structures for offshore energy generation for instance.

60% of the jobs in the sector are provided by maritime equipment and system suppliers. These produce the most innovative equipment and systems for shipping and for the development of other blue growth activities.

Building ships is a complex engineering process which involves a wide range of specialists and professionals. Some companies have identified more than 120 different occupations within the company. 90% of the jobs require high skills and specific qualification and certifications, usually coming from high vocational education and training (VET) or University background.

Welders, pipe fitters, electricians, engineers, Naval Architects or designers are always on high demand in maritime technology companies.

Some of the main and most demanded jobs are the following:

- Ships Architect-Designer - Assistant or Apprentice

Naval Architects or Designers: They are responsible for designing the ship, stability calculations, resistance estimations, preparation of 3D production model and 2D production drawings.

- Interior Designer

- Ship Building- Materials Sourcing - Logistics

- Electrical and Electronics Engineer - Assistant – Apprentice

Electricians: Electricians are responsible for installation of all the electric cables on board the ship, based on the cable routing plans. They also install all the electrical and electronic equipment, navigational equipment in the bridge and radar, lighting, control panels, main electrical control room panels, etc. Electricians must be adept in reading equipment positioning drawings, and most importantly, equipment end drawings (those that represent where cables are attached to equipment). Electricians are also employed in the maintenance department of shipyards.

- Plumbing Engineer - Assistant - Apprentice

Plumbers and pipe fitters: They are important because the water fittings and supply in a ship has to be perfect. The aspect of piping in ships involves maximum attention towards the ability to read and understand isometric piping layout drawings and Piping and Instrumentation drawings. Plumbers are specialized in the installation of all pipelines inside a ship, along with all kinds of pipe fittings like valves, flanges, etc.

- Electronics Engineer - Assistant - Apprentice

- Painter – Gel Coats - Sprays etc.

- Welder - Metal Construction - Framing

Welders are highly skilled and essential workforce in the sector. The industry demands certified welders who can reach the highest quality standards and have zero defects on Arc welding, MIG, TIG, etc. They are responsible for welding all the metal structures that make up the ship, which includes the hull plates, frames, girders, tanks, foundations, pipes, etc.

- Surveying - Insurance Assessor

- Painter – Gel Coats - Sprays etc.

- Welder - Metal Construction - Framing

With a welding technician

How did you become interested in the marine environment?

As many other in the maritime industry, I grew up next to the sea so I could easily discover the industry during leisure or trades. I am now working for a company that builds submarines which is an extraordinary product for me.

What was your entry route?

I carried out a 2-year VET programme on Design and Realisation of Industrial Boilers followed by two certificates which I did in parallel for one year: a training on Metalworking and Welding and, the most important one, a certificate in International Welding Technologist (IWT).

What are your tasks?

Simplify the welding procedures, research about technologies and welding techniques used in other companies, oversee the purchase and the replacement of welding machines, ensure the smooth running of the machines in the workshop, provide technical support to workers, carry out long term or short-term studies to improve the welding quality.

What do you enjoy most about your job?

What do you enjoy most about your job? The variety of tasks, the combination of technical and concrete aspects, the constant contact with the field and the production, the product itself and its history. On the other hand, the mobility and travelling opportunities to work in projects that the company has abroad.

Do you have any tips for someone considering a similar career to yours?

You must try to do as many apprenticeships and trainings as possible during your studies as it will allow you to see if the job meets your expectations. You must also really invest yourself in your training and try to leave good image of your passage in the company. Do not hesitate to go to others, to go spend time in other services to discover and be sure to move into the best branch for you.

With a Performance Manager

Description

Ensuring the continuous improvement process so that daily operation runs in a safe, efficient and cost-effective manner, and supporting the company in its transformation plans to increase productivity. The business philosophy is that you must criticize the system to improve it.

Tasks

- Creating and stimulating a culture of performance and improvement along the company adapted to the different departments and tasks always keeping in mind that the actions must remain relevant to the objectives of the company

- Accompany teams during this process

- Take care of communication, training and animation for multidisciplinary teams• Create and implement productivity tools

- Create and implement productivity tools

Skills Needed

- Planning objectives and designing development activities

- Progress monitoring

- Identifying areas of development

- Listening and asking the right questions

- Interpersonal skills

- Ability to synthesize

- Pragmatism

- Rigor

- Dynamism

- Autonomy

- Constant questioning

- Ability to engage and support others

Working hours, patterns and environment career

Usual working hours for a technical worker, about 8 hours per day.

The framework often changes according to the departments and objectives to deal with. She can be in workshops or offices and therefore work with young technical workers or senior officials.

The work is intellectual most of the time, even psychological sometimes.

Qualification levels

Technical background -Engineering or VET-

Future of the career

This position allows you to reach many different areas. It is a good gateway to be responsible for performance and therefore to manage a fully-fledged entity in the long term.

The job will become very important in the next years because it enables the company to reduce production costs without cutting on staff. The service in which she is located is itself expanding, it will grow from 2 members to 5 in the future.

How did you become interested in the marine environment?

I had always gravitated around the sea since i grew up there. I then engaged and sailed with the Merchant Navy.

What was your entry route?

I am was a mechanic in the merchant navy after training at the Ecole Nationale de la Marine Marchande in France. After sailing for some time, i re-skilled through a 2-year training in materials engineering science then completed a bachelor's degree in Production Management. Finally, i completed a Certificate in Metallurgy to be a line leader. This certification is an important plus to work in my position.

What do you enjoy most about your job?

Human contact. It is always complicated at the beginning because performance analysis is often equated with job reduction. But then people realize that it is them who have the ideas and it is up to them to put those ideas in place, which brings satisfaction to everyone and a cost reduction.

Do you have any tips for someone considering a similar career to yours?

You have to be modest, question yourself all the time and know how to seize opportunities.

It is an industry that is always evolving, providing career opportunities and new jobs. There are also good bridges with other companies because the industry is like a big family, people are in solidarity with each other and there is a real sense of belonging and pride.

Despite the sector has traditionally been considered as a “male” sector the number of women is growing. At the workplace collaboration with other workers is very good and fruitful.